Basic Rhodamine B 540%

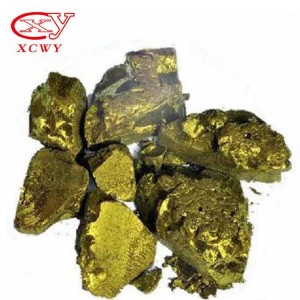

Basic Rhodamine B 540% is a kind of basic dyes, which has appearance of shinning dark green powder.

It is easily soluble in water and alcohol.After soluble in water or alcohol, the color is pink red with yellow-green fluorescence.

Basic rhodamine B 540% has characteristic of high light fastness, bright color, strong dyeing power and good transparency.

Therefore, basic rhodamine B 540% dye is widely used for dyeing paper, egg trays, mosquito coils, incense stick linen, wool, cotton, leather and other fabrics.

Basic Rhodamine B 540%Specification

» Basic Dye Name: Rhodamine B 540%

» Colour Index: C.I.Basic Violet 10(45170)

» CAS No.: 81-88-9

» Appearance: Shinning Dark Green Even Fluffy Powder .

» Usage: Ink Dyestuffs, Leather Dyestuffs, Paper Dyestuffs,Paint Dyestuffs Plastic Dyestuffs ,Textile Dyestuffs,

Mosquito coils dyestuff, Incense Dyestuffs, Egg Tray Dyestuffs

Basic Rhodamine B 540% Basic information

|

Basic Information |

|

|

Product Name |

Basic Rhodamine B |

|

Colour Index |

C.I. Basic Violet 10 |

|

Colour Index No. |

45170 |

|

CAS No. |

81-88-9 |

|

Specification |

|

|

Shade |

Similar With Standard |

| Strength | 100% |

|

Appearance |

Shinning Dark Green Even Fluffy Powder . |

| Moisture %≤ | 1.0 |

|

Insoluble Matter %≤ |

0.5 |

|

Properties |

Very soluble in water and alcohol |

Basic rhodamine B 540% application:

» It is mainly used for dyeing waxed paper, typewriter paper and glossy paper in paper-making industry.

» It can also be used for dyeing acrylic and cotton fibers.

» It reacts with phosphotungstic molybdic acid to form precipitation, which is used to make paints and paints.

» It can also be used for dyeing linen, wheat straw and leather products.

The main functions of Basic rhodamine B 540% in dyeing

» Increase the solubility of disperse dyes appropriately.

» Promote the adsorption of disperse dyes on the surface of fibers.

» Plasticize the fibers or increase the swelling degree to accelerate the diffusion rate of disperse dyes in the fibers.

» Improve the dispersion stability of dyes. Generally, the auxiliaries used in high-tide and high-pressure dyeing of polyester fibers include carriers for plasticizing fibers, surfactants for solubilizing disperse dyes or stabilizing dye suspensions. Dyeing auxiliaries play an important role in the dyeing of polyester fibers.

Contact person: Miss Jessie Geng

Email:jessie@xcwychem.com

Mobilephone/Whatsapp: +86-13503270825