Pigment dispersant is a key additive used to stabilize the dispersion state of pigment particles in liquid media such as coatings, inks, plastics, ceramic glazes, etc. Their main function is to prevent pigment particles from aggregating and settling, thereby ensuring color uniformity, strength, glossiness, and long-term stability of the product.

Pigment Dispersant Function

1. Wetting effect: Reduce the interfacial tension between pigment particles and liquid media, promote the penetration of media into the voids of pigment aggregates (agglomerates and aggregates), and lay the foundation for subsequent depolymerization.

2. Decomposition/dispersion effect: With the assistance of mechanical force (grinding, stirring), dispersants adsorb onto the surface of pigment particles, weakening the cohesion between particles (van der Waals force, etc.), helping to break down large aggregates (agglomerates) and achieve or approach the fineness of primary particles.

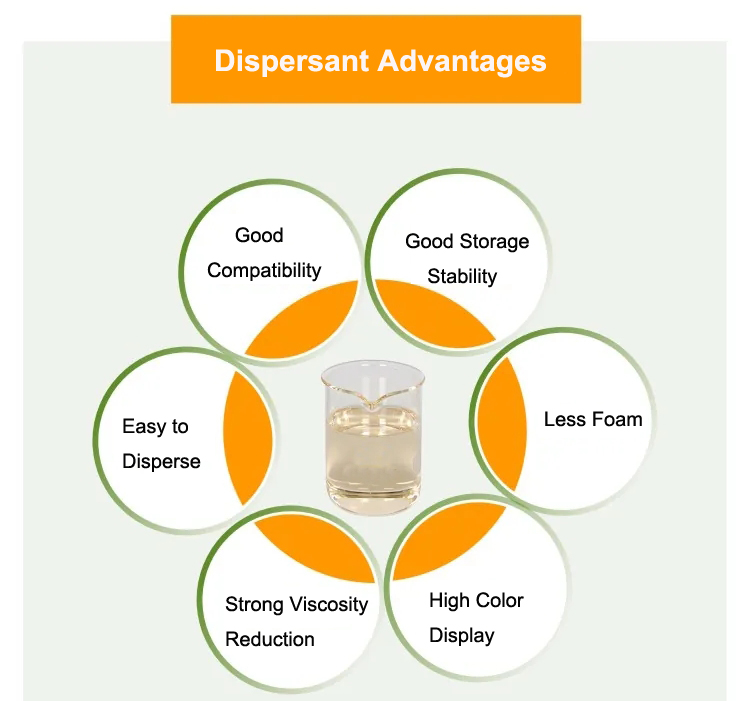

3. Stabilizing effect (the most critical function): prevents pigment particles that have been dispersed from re aggregating (flocculation) and settling. This is achieved through the aforementioned electrostatic repulsion, spatial hindrance, or the synergistic effect of both. Good stability is the foundation for maintaining the long-term uniformity and performance of pigment dispersion.

4. Viscosity reducing effect: By effectively dispersing pigment particles, reducing the interaction force between particles, significantly reducing the viscosity of the entire pigment slurry or final product, improving fluidity, leveling, and workability.

5. Improve coloring power and glossiness: Fully dispersed pigment particles can reflect or absorb light more effectively, exhibiting higher color intensity (coloring power). Meanwhile, small and uniformly dispersed particles can form a smoother coating surface, improving glossiness.

6. Preventing floating and blooming: In systems containing multiple pigments, dispersants help stabilize the dispersion state of different pigments and prevent pigment separation phenomena (floating and blooming) caused by differences in density, particle size, or surface properties.

7. Improve storage stability: prevent pigments from settling and clumping during storage, and ensure that the product is easy to mix again after opening the can.

Our factory can not only produce pigment dispersant, but also can produce other chemical agent including wetting agent, leveling agent and defoaming agent. Welcome your inquiry.

Contact person: Miss Jessie Geng

Email:jessie@xcwychem.com

Mobilephone/Whatsapp: +86-13503270825

Post time: Aug-06-2025