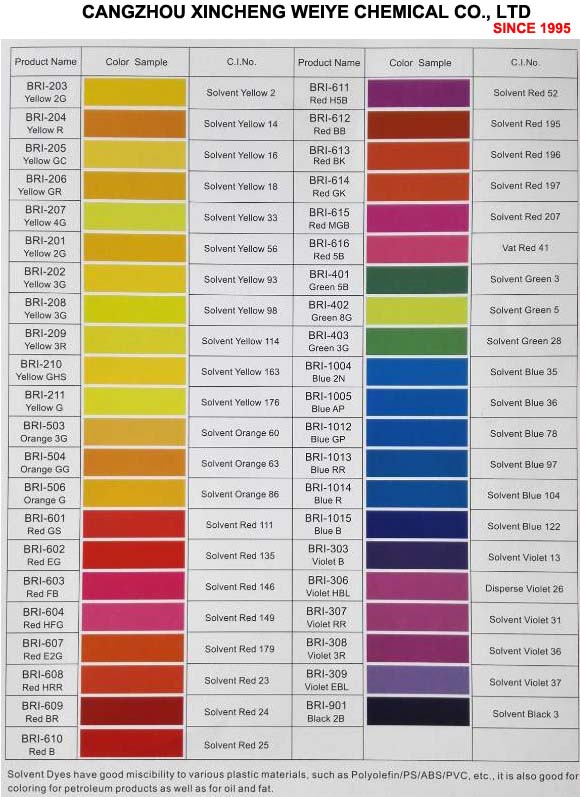

As professional solvent dyes manufacturer in China, we supply reliable quality solvent dyes/colorant. Our solvent dyes consists of solvent red dyes, solvent blue dyes, solvent yellow dyes, solvent orange dyes, solvent black dyes and solvent green dyes. They are widely used for coloring of plastic, masterbatch, paint, furnish, rubber and coating.

However, do you know the main factors affecting dyeing process with solvent dyes?

1. Dye properties

The structure of dye and its molecular size and shape determine the solubility and diffusion of dye and the affinity between dye and fiber.

2. Properties and concentration of additives

There are many kinds of auxiliaries, such as acid, basic, salt, oxidant, reductant, dispersant, leveling agent and dyeing promoter in both dyes and dyeing bath. They have an impact on the solubility, dispersion stability, diffusion in dyeing bath and fiber, and dyeing rate of dyes.

3. Process parameters

Process parameters include dye concentration, bath ratio, temperature, temperature rising and falling rate, holding time, setting of positive and negative circulation time of dye solution, and adding method of auxiliaries, all affect the dye uptake process.

4. Fiber properties

The structure and surface characteristics of the fiber itself will also affect the dye uptake process. For example, the ultra-fine fiber has small radius, large specific surface area, fast adsorption speed and large amount of dye on the surface. The more easily the dye diffuses into the fiber, the faster the dye uptake rate.

Contact person: Miss Jessie Geng

Email:jessie@xcwychem.com

Mobilephone/Whatsapp: +86-13503270825

Post time: Feb-22-2021