1. Direct dyes:

The thermal stability of the direct dye is relatively good. The direct dye can be added to soda ash soft water for solubilization. When the material is mixed, the dye is first mixed into a slurry with cold soft water, then stirred and dissolved with boiling soft water, diluted with heating water, and then added to the specified amount of water after cooling.

2. Reactive dyes:

This kind of dyestuff is not heat-resistant and easy to hydrolyze at high temperature. It is better to use cold soft water to adjust it into paste shape. Then, according to the hydrolysis stability of different dyestuffs, use soft water at appropriate temperature to dissolve, heat soft water to dilute, and add soft water to the specified liquid volume after cooling.

Low temperature type (type X): cold water or 30-35 ℃ warm water (basically eliminated)

70-80 ℃ hot water for high temperature type (K type, HE type, etc.)

60-70 ℃ hot water for medium temperature type (KN, M type)

Use 90 ℃ hot water with low solubility

3. Vat dyes:

The dissolving process of vat dye is a reducing reaction process. When dissolving, the dissolving temperature should be determined according to the reducing conditions of the used reductant. For example, the commonly used reductant of vat dyes is sodium sulfite, and the best temperature in solution is 60 ℃, too high temperature will lead to a large amount of decomposition of sodium sulfite.

(1) Full bath method:

Put the dye into the dye cup, add red oil and a small amount of warm and soft water to mix, then add the specified amount of caustic soda and insurance powder, then add soft water to the required bath volume, and reduce at 55 ℃.

(2) Dry cylinder method:

Put the dye into the dye cup, add red oil and a small amount of warm and soft water to mix, and then add two-thirds of the amount of caustic soda and baking powder, so that the amount of dye solution is one-third of the total amount. The temperature of dissolution shall be determined according to the reduction conditions of the reducing agent used. Add the remaining caustic soda and baking powder into the dye cup, and add soft water to the required bath volume.

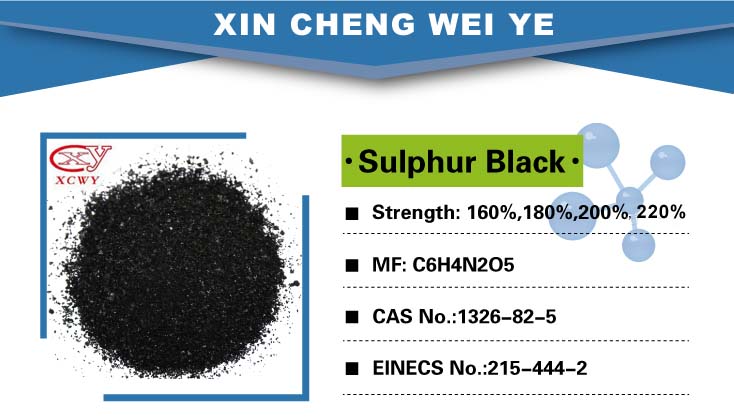

4..Sulphur dyes:

Accurately weigh the required amount of dye into a beaker, mix it with cold soft water into a paste, then add the previously dissolved sodium sulfide dye solution, and boil for 10min. Heat soft water to dilute, add soft water to the specified volume after cooling.

5.Disperse dyes:

Disperse dyes tend to crystallize and precipitate when the temperature is too high. It is advisable to mix the slurry with cold soft water first, then use cold soft water to mix the slurry below 40 ℃ and add soft water to the specified liquid volume.

6. Acid dyes:

Acid dyes have relatively good heat-resistant stability. When acid dyes are used, the dye is first mixed into a slurry with cold soft water, then stirred and dissolved with boiling soft water, heated and diluted with soft water, and then added with soft water to the specified liquid volume after cooling.

7. Cationic dyes:

The thermal stability of cationic dyes is relatively good. The dye is first mixed into a slurry with concentrated acetic acid (solubilizing aid), then stirred and dissolved with boiling soft water, diluted with heating water, cooled and added with soft water to the specified liquid volume.

This article is from Rhodamine B dye manufacturer-Cangzhou Xincheng Weiye Chemical. Any more information, welcome contact with us.

Contact person: Miss Jessie Geng

Email:jessie@xcwychem.com

Mobilephone/Whatsapp: +86-13503270825

Post time: Feb-25-2020